High-speed, high-precision tube bending powered by intelligent CNC control

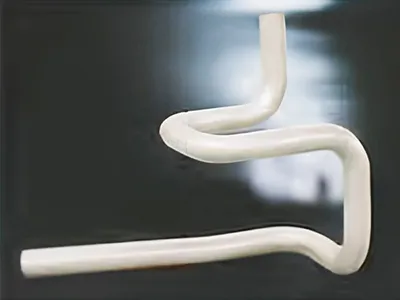

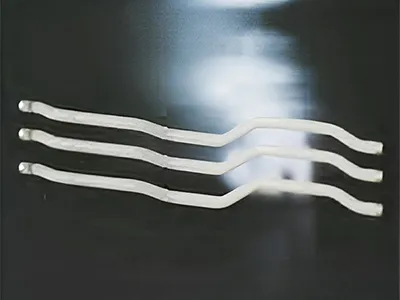

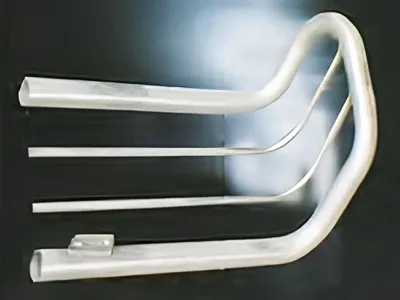

The CNC tube bending machine delivers rapid bending speeds, reaching up to 85 degrees per second, with bending accuracy of ±0.1 degrees. It is designed to meet diverse bending process requirements and is widely used in the production of parts for the automotive industry, health and fitness equipment, furniture, medical devices, and construction machinery.

The CNC control system is the core of this machine, providing programmable control, an intuitive operator interface, process parameter settings, and self-diagnostic capabilities. This system not only enhances processing efficiency and quality but also minimizes labor intensity and operational complexity.

The Multi-S series tube bending machine is a multi-layer die bender, equipped with either servo motors or hydraulic proportional servo valves, depending on the model. This machine offers multi-axis control and can bend tubes with diameters up to 325mm. It features an IPC (Industrial Personal Computer) and a touchscreen display for easy operation.

| Model | DW63CNC-5A-3S | DW75CNC-5A-3S | DW89CNC-5A-3S | DW115CNC-5A-3S |

| Max. bending capacity (diameter×wall thickness) |

∅63mm×4mm | ∅75mm×4mm | ∅89mm×8mm | ∅115mm×8mm |

| Max. bending radius | R250mm | R250mm | R250mm | R350mm |

| Min. bending radius | Depending on tube diameter | Depending on tube diameter | Depending on tube diameter | Depending on tube diameter |

| Max. bending angle | 190° | 190° | 190° | 190° |

| Max. feeding length | 3000mm | 3000mm | 3000mm | 3000mm |

| Feeding method | Direct feed or clamping feed | Direct feed or clamping feed | Direct feed or clamping feed | Direct feed or clamping feed |

| Working Speed Bending | Max. 85deg/sec | Max. 40deg/sec | Max. 30deg/sec | Max. 30deg/sec |

| Working Speed Rotating | Max. 200deg/sec | Max. 160deg/sec | Max. 160deg/sec | Max. 160deg/sec |

| Working Speed Feeding | Max. 1000mm/sec | Max. 800mm/sec | Max. 800mm/sec | Max. 800mm/sec |

| Working Accuracy Bending | ±0.1° | ±0.1° | ±0.1° | ±0.1° |

| Working Accuracy Rotating | ±0.1° | ±0.1° | ±0.1° | ±0.1° |

| Working Accuracy Feeding | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm |

| Data input method | 1. XYZ coordinates 2. YBC data | 1. XYZ coordinates 2. YBC data | 1. XYZ coordinates 2. YBC data | 1. XYZ coordinates 2. YBC data |

| Bending method | Servo bending 1kW (more than 3 axis) | Servo bending 2kW (more than 3 axis) | Servo bending 5kW (more than 3 axis) | Servo bending 5kW (more than 3 axis) |

| Rotating servo power | 750W | 1kW | 1.5kW | 1.5kW |

| Feeding servo power | 1kW | 1.5kW | 2kW | 3.5kW |

| Max. bends | 16 bends (PLC) 33 bends (industrial PC) | |||

| Max. bending storage | 1000 (PLC) 2 million (industrial PC) | |||

| Hydraulic motor power | 5.5kW | 7.5kW | 11kW | 22kW |

| Max. pressure of system (adjustable) | 12MPa | 12MPa | 14MPa | 14MPa |

| Bending radius difference | Max. 80mm | Max. 90mm | Max. 100mm | Max. 110mm |

| Machine weight | 3800kg | 4500kg | 5500kg | 8000kg |

| Machine dimensions | 5200×1300×1750mm | 5200×1350×1230mm | 5650×1350×1360mm | 5700×1350×1400mm |

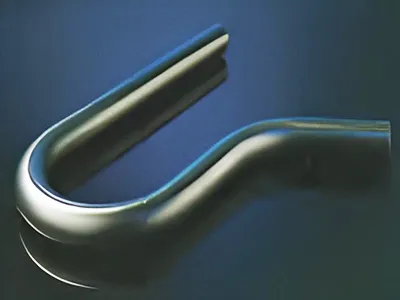

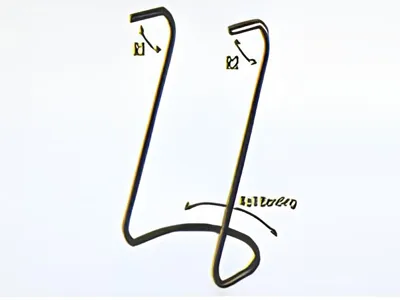

The CNC push-bend pipe bending machine series offers advanced push and roll bending capabilities, providing versatile solutions for complex tube forming. These machines are designed to handle a wide range of bending applications, ensuring precision and efficiency. The push bending and roll bending methods allow for the creation of intricate shapes and large radius bends, catering to diverse industry needs.

| Model | DW25CNCX4A-3SV | DW38CNCX4A-3SV | DW50CNCX4A-3SV | DW63CNCX4A-3SV | DW75CNCX4A-3SV | ||

| Max. bending capability (diameter×wall thickness) | ∅25×1.6mm | ∅38×2mm | ∅50×2mm | ∅63×3mm | ∅75mm×3mm | ||

| Max. feeding length | 1500 | 2500 | 3000 | 3000 | 3000 | ||

| Bending radius | Bending | Round tube | 1.5D-4D | 1.5D-54D | 1.5D-5D | 1.5D-5D | 1.5D-3.3D |

| Rectangular tube | 2.5D-4D | 2D-5D | 2.5D-5D | 2D-4D | 2.5D-3.3D | ||

| Push/roll bending | Round tube | 6D-∞ | 6D-∞ | 6D-∞ | 6D-∞ | Full scale | |

| Rectangular tube | 8D-∞ | 7D-∞ | 7D-∞ | 8D-∞ | 10D-∞ | ||

| Max. bending radius | 120 | 175 | 200 | 250 | 300 | ||

| Max. bending angle | 190° | 190° | 190° | 190 | 190° | ||

| Bending accuracy | ±0.1° | ±0.1° | ±0.1° | ±0.1° | ±0.1° | ||

| Rotating accuracy | ±0.1° | ±0.1° | ±0.1° | ±0.1° | ±0.1° | ||

| Feeding accuracy | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ||

| Machine dimensions | 300×950×145cm | 380×135×122cm | 430×90×130cm | 430×90×140cm | 450×191×185cm | ||

| Machine weight | 1500kg | 3600kg | 4500kg | 5500kg | 7500kg | ||

Got questions about our metalworking machines? We’re here to help you choose the right solution for your business. Contact us now!